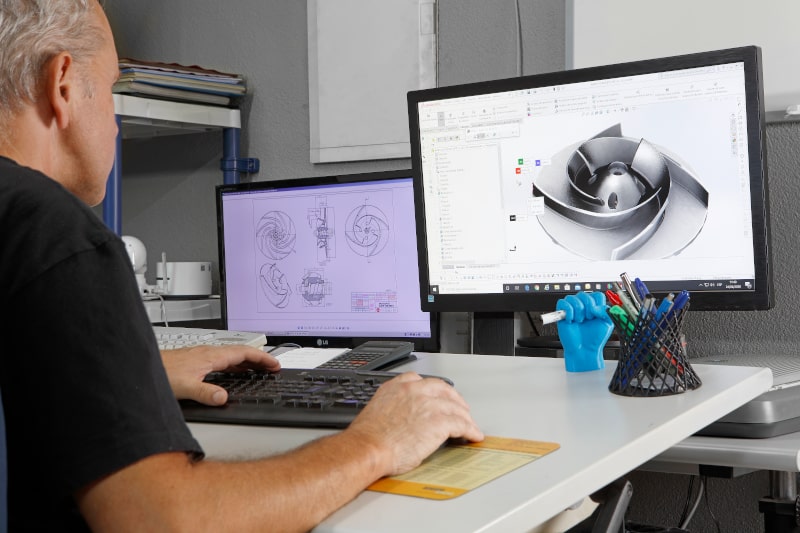

As well as having state-of-the-art means and a professional production team with experience spanning more than four decades, at Refincel we are committed to the innovation and quality of each and every one of our production processes. That’s why our technical office is one of the pillars of our work as specialists in spare parts for the paper industry, among others.

The team at our technical office performs essential tasks enabling us to offer an integral advisory service including the study and production of parts and spares fully customised for each customer. From the study of the different materials and their applications in specific cases, to the adjustments required to improve the performance of certain parts or spares, the aim of our technical office is always the same: to offer you a production service adapted to your needs and guaranteed to improve your production processes.

All of the materials we use in our production process are supervised by our technical office. In the majority of cases we work with stainless steel. We use AIS 329/316 for pump spares and parts. We also use 18-2 as an anti-abrasive material, widely used in parts for the purification process, or 17.4.PH, a highly resistant stainless steel, which withstands wear and functions perfectly in the production of parts and spares for refiners.

Commitment to the innovation and development of our technical office means that we can offer an integral analysis and design service for special parts. Do you need help? Consult our professionals.